The 10 Best Offers for Brazing Device - February 2026

We already helped 10 million customers this year!

- [HEAT RESISTANT DESIGN] This silicone mat can withstand high temperatures, making it for soldering and brazing tasks without losing its integrity.

- [ANTI STATIC PROTECTION] Equipped with anti-static features, this mat protects delicate electronic devices from electrostatic discharge during repairs.

- [AMPLE WORKSPACE] With generous dimensions of 34x23cm, it provides plenty of room for soldering irons, tools, and gadgets, enhancing your efficiency.

- [STABLE COMPONENT HOLDING] The mat's keeps small components and tools in place, reducing the risk of misplacement during intricate repair tasks.

- [MULTI-PURPOSE APPLICATION] Suitable for a variety of electronics including phones, watches, and computers, this mat is perfect for any repair enthusiast.

| Colour | Manufacturer | Weight |

| - | Homeponnew | - |

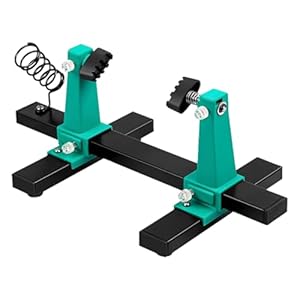

- Multi-angle adjustment: With the rail sliding mechanism, this PCB holder allows fluid adjustments at different angles for stable component holding and vibration-free clamping on different PCB sizes, ideal for precise soldering work and detailed electronics repairs in various workshop environments.

- MATERIAL FOR LONG TIME USE This PCB holder focuses on long-term integrity through durable metal construction and wear resistance. Users can handle sensitive electronics projects with confidence without concern about equipment failure, as the material provides lasting stability and does not show shape change even with regular use, ensuring reliable grip.

- PORTABLE TO USE Thanks to the easy storage and compact footprint, this soldering stand is lightweight and portable and provides instant readiness. It supports a seamless project flow indoors and outdoors, making it versatile for mobile applications. The portable features ensure tools are organised and always ready for immediate use.

- Easy and user-friendly handling: With the integrated adhesive residue removal area and multiple accessory storage compartments, the PCB holder ensures that all necessary utensils are always at hand. This allows users to fully concentrate during detailed electronics projects such as soldering or repairs, without unnecessary interruptions. The clear organisation of all components and tools supports a smooth workflow and increases the efficiency

- Error Reduction Design This PCB holder for soldering reduces errors by advanced calibration scales and alignment slots, which ensure stable positioning of components. This increases repair precision and reduces the error rate during electronic work, making it a reliable solution for precise soldering operations.

| Colour | Manufacturer | Weight |

| Single Attributes | Eoixuqba | - |

- [ HEAT RESISTANCE] Constructed from silicone, this soldering mat withstands high temperatures without compromising its structure during intense soldering or brazing tasks.

- [ANTI-STATIC FUNCTIONALITY] Protects sensitive electronic devices from potential damage caused by electrostatic discharge during repair operations.

- [GENEROUS SIZE FOR EFFICIENCY] The 34x23cm dimensions provide sufficient workspace for all your soldering needs while keeping tools organized and accessible.

- [COMPONENT HOLDING DESIGN] Designed to hold small parts securely in place to prevent misplacement or rolling away during intricate repair tasks.

- [MULTI-FUNCTIONAL APPLICATIONS] Suitable for various electronic devices including phones and computers, this mat is perfect for both hobbyists and professionals engaged in repairs.

| Colour | Manufacturer | Weight |

| As Picture Show | Gettimore | 210 g |

- Multifunctional tool: this PCB holder is designed for various motherboard repairs and can be adjusted to different sizes to ensure multifunctional support and increased efficiency.

- Reliable stability: with 5 adjustable clamps, our PCB holder holds motherboards of different thicknesses firmly and thus ensures an unshakable hold during soldering.

- Convenient control: by tightening or loosening the button, you can achieve 360 degree rotation for convenient operation, so that the motherboard can be fixed at any angle, which improves the workflow.

- Versatile hold: benefit from a large clamping distance of 200 mm and an adjustable opening distance of 170 mm with the soldering iron stand. Effortlessly attach your circuits to the versatile and sturdy PCB holder tailored to your diverse repair needs.

- Easy to remove: Equipped with non-slip rubber pads, this circuit board holder increases friction and prevents burns, while the removable stand with its high temperature resistant materials supports most soldering iron pins.

| Colour | Manufacturer | Weight |

| A | ulapithi | - |

- Sturdy Material: Crafted from excellent materials, the PCB holder provides enhanced durability and maintains its form without warping, ensuring consistent performance when used repeatedly for organizing or repairing electronics components

- Error Reduction Design: This PCB holder for soldering minimizes errors through advanced calibration scales and alignment slots, ensuring steady positioning of components for enhanced repair precision

- Flexible Positioning System: This circuit board holder utilizes a rail sliding mechanism with multi-angle adjustability , providing users the ability to secure boards firmly while eliminating vibrations during use, which is especially beneficial when working on complex circuits or delicate electronic projects

- Easy to Operate: The PCB vise features a glue removal area and accessory storage slots, promoting an efficiency-boosting layout that keeps tools and components neatly arranged, ensuring a smooth workflow for electronics assembly or repair tasks in any workshop setting

- Portable to Use: With a pay attention to easy storage and a compact footprint, this soldering holder is lightweight and portable, offering instant access readiness. It supports seamless project continuity whether indoors or outdoors

| Colour | Manufacturer | Weight |

| Single Attribute | Generic | - |

- Sturdy Material: Crafted from excellent materials, the PCB holder provides enhanced durability and maintains its form without warping, ensuring consistent performance when used repeatedly for organizing or repairing electronics components

- Optimized Component Alignment: The PCB holder for soldering features alignment slots that ensure ultra-high accuracy, supporting error-free repairs and improving overall precision, an tool for meticulous electronics work

- Multi-angle Adjustability: The circuit board holder features a rail sliding mechanism that allows smooth multi-angle adjustments, ensuring steady component hold and vibration-free clamping for diverse board sizes, making it ideal for intricate soldering tasks or detailed electronic repairs in various workshop settings

- Convenient to Use: Designed with a chip fixation zone and organized compartments, this PCB vise optimizes work functionality, enabling seamless transitions between steps while handling complex repairs or prototype developments effectively

- Portable to Use: With a pay attention to easy storage and a compact footprint, this soldering holder is lightweight and portable, offering instant access readiness. It supports seamless project continuity whether indoors or outdoors

| Colour | Manufacturer | Weight |

| Single Attribute | Yumneo | - |

- Assured Durability: The PCB holder features high-quality metal construction that ensures long-term structural integrity and resists warping, making it ideal for securely holding circuit boards during assembly or testing while preventing damage from wear over time in professional environments

- Enhanced Soldering Stability: With integrated alignment slots and precise calibration scales, this PCB holder for soldering boosts repair precision and reduces errors, offering a dependable solution for complex circuit board tasks

- Adaptable Board Support: The circuit board holder's rail sliding mechanism enables multi-angle adjustability, ensuring a reliable grip without vibrations across diverse board sizes, enhancing efficiency whether you're assembling prototypes or troubleshooting electronics in demanding environments

- Easy to Operate: The PCB vise features a glue removal area and accessory storage slots, promoting an efficiency-boosting layout that keeps tools and components neatly arranged, ensuring a smooth workflow for electronics assembly or repair tasks in any workshop setting

- Lightweight and Portable: The soldering holder provides easy storage and a compact footprint, making it lightweight and portable for convenient carry. Its instant access readiness ensures tools are organized and available when needed, ideal for both workshop and outdoors use

| Colour | Manufacturer | Weight |

| Single Attribute | SVCEQZE | - |

- High-quality Material: With a pay attention to long-term integrity, this PCB holder combines high-quality metal construction and resistant to wear, enabling users to handle sensitive electronic projects confidently without worrying about equipment failure

- Accurate Calibration Support: The PCB holder for soldering provides reliable calibration scales and alignment slots, enabling users to achieve ultra-high accuracy while reducing the risk of misalignment, perfect for detailed electronic assembly

- Stable Control Feature: With its rail sliding mechanism supporting multi-angle adjustability, this circuit board holder ensures steady component hold and eliminates vibrations, catering to varying board dimensions and simplifying intricate tasks like wiring, diagnostics, or hands-free soldering operations

- Handy to Use: This PCB vise incorporates a chip fixation zone along with designated areas for glue removal and accessory storage, streamlining operatings by reducing clutter, which is ideal for precise soldering or intricate circuit board modifications

- Lightweight and Portable: The soldering holder provides easy storage and a compact footprint, making it lightweight and portable for convenient carry. Its instant access readiness ensures tools are organized and available when needed, ideal for both workshop and outdoors use

| Colour | Manufacturer | Weight |

| Single Attribute | Arrovarp | - |

- Strong Material: The PCB holder's robust metal structure prevents damage and deformation, allowing it to securely hold printed circuit boards during intricate tasks like soldering or inspection while extending its lifespan through daily usage

- Accurate Calibration Support: The PCB holder for soldering provides reliable calibration scales and alignment slots, enabling users to achieve ultra-high accuracy while reducing the risk of misalignment, perfect for detailed electronic assembly

- Enhanced Stability Design: Equipped with a rail sliding mechanism, this circuit board holder has multi-angle adjustability to maintain a steady component hold and vibration-free clamping, accommodating boards of different sizes and proving highly effective during precision-based assembly or testing processes

- Convenient to Use: Designed with a chip fixation zone and organized compartments, this PCB vise optimizes work functionality, enabling seamless transitions between steps while handling complex repairs or prototype developments effectively

- Portable to Use: With a pay attention to easy storage and a compact footprint, this soldering holder is lightweight and portable, offering instant access readiness. It supports seamless project continuity whether indoors or outdoors

| Colour | Manufacturer | Weight |

| Single Attribute | Generic | - |

General information about Brazing Device:

Brazing devices are essential tools used in various industries for joining metal parts together by melting a filler metal and then cooling it to bond the parts. This process, known as brazing, provides a strong and durable joint that is resistant to high temperatures and has excellent mechanical properties. Brazing devices are widely used in automotive, aerospace, electronics, and plumbing industries, among others.

One of the key components of a brazing device is the gas torch. The torch provides the necessary heat to melt the filler metal and create the bond between the metal parts. Brazing devices also include a fuel gas supply and an oxygen supply, which are used to create the flame required for heating. These devices may use various types of fuel gases, such as acetylene, propane, or natural gas, depending on the specific application.

In addition to the torch and fuel supply, brazing devices often have additional features to ensure efficient and precise brazing. Temperature controls and regulators allow users to adjust the heat output to meet the specific requirements of the brazing process. Some brazing devices also have integrated safety features, such as flame sensors and automatic shut-off valves, to prevent accidents and ensure user safety.

The use of brazing devices offers several advantages over other joining methods. Brazed joints are known for their high strength and resistance to vibration and thermal cycles. This makes them particularly suitable for applications exposed to harsh conditions, such as parts used in jet engines or automotive exhaust systems. Brazing also allows the joining of dissimilar metals, expanding the range of applications in which it can be used.

In conclusion, brazing devices are essential tools used in various industries for joining metal parts together. They utilize gas torches, fuel gas supplies, and oxygen supplies to provide the necessary heat for melting the filler metal and creating strong, durable bonds. With their numerous features and advantages, brazing devices play a crucial role in facilitating efficient and reliable joining processes across a wide range of applications.

** "Free Delivery" means that this is possible under the given conditions at the time of data retrieval from the relevant provider, but cannot be guaranteed. It is technically not possible to provide information in real-time. The shipping costs may vary under certain circumstances (different provider, place of delivery, etc.). The shipping costs shown in the further ordering process apply.

Other IMPORTANT INFORMATION that we ask you to take note of:

We may receive a commission if you make a purchase via the links on our site. This has no impact on the placement of the products on our site. Our website is part of amazon associates program - Amazon, Amazon Prime, the Amazon Logo and Amazon Prime Logo are registered trademarks of Amazon, Inc. or its affiliates.

Disclaimer:

1. The prices shown may have risen since the time we last updated them.

2. The actual price of the product on the seller’s site at the time of purchase will govern the sale.

3. It is not technically possible for the prices displayed above to be updated in real-time.